SGP Film Factory

The ideal laminated glass interlayer film for building curtain walls should meet the following requirements:

1. It has high bonding ability to glass and strong tear strength, which can prevent the glass from scattering when it breaks.

2. It has strong protective ability to prevent the damage of natural forces and manpower. Strong resistance to strong winds, earthquakes, violence, theft, etc.

3. Can withstand the sudden impact of indoor personnel, prevent the glass from scattering or the whole out, to avoid indoor personnel flying out of the fall.

4. There is enough residual bearing capacity, and the whole piece will not fall off when the glass is broken and then deformed.

5. The interlayer film has a large shear modulus, so that the two glasses are bent as much as possible, thereby increasing the bearing capacity and bending rigidity of the glass, reducing the thickness of the glass, and reducing the weight of the glass.

6. Colorless and transparent, able to withstand the effects of ultraviolet light, water vapor and external climate change, long-term use without yellowing discoloration.

The PVB interlayer film currently used cannot fully meet the above requirements. However, Dongguan Qun'an Plastic Industry Co., Ltd. recently developed a higher performance SGP film for curtain wall laminated glass, to adapt to super high-rise building curtain wall, large-span lighting roof, super large-sized laminated glass, all-glass structure and other laminated glass. High standard requirements.

Qun'an SGP ionic interlayer film has many excellent properties.

It has high strength and shear modulus and excellent mechanical properties: SGP has a shear modulus of more than 50 times that of PVB and a tear strength 5 times higher than PVB. After the SGP is glued, the glue layer between the two pieces of glass will not slip substantially when the glass is stressed. The two pieces of glass work as a single piece of glass of equal thickness. In this way, the bearing capacity is twice the bearing capacity of the PVB laminated glass of equal thickness; at the same time, the SGP laminated glass has a bending deflection of only 1/4 of the PVB laminated glass under the same load and equal thickness. As the bearing capacity increases, the deflection decreases and the glass thickness decreases accordingly. It is possible to reduce the amount of glass by about 40%, which also reduces the weight of the curtain wall. Not only is it beneficial to the main structure design, but also the material saving is energy-saving, because the production of each standard box float glass consumes 16Kg of standard coal and consumes 7.5 degrees of electricity. If tempering, homogenization, etc. are added, the energy consumption will be even more.

It has good edge stability and can be used without being sealed. Edge stability refers to the durability of the edge of the laminated glass exposed to atmospheric conditions. PVB is not resistant to moisture, it is easy to open and separate under the action of water vapor, and the exposed edge is required for edge sealing. SGP adhesive has good edge stability, is not sensitive to moisture, and will not be opened or separated under exposed conditions. It can be used for open edge without edge sealing. Therefore, the SGP laminated glass can be conveniently used for the components of the exposed edge such as the baffle, the canopy, the external decorative glass wing, the glass sun visor, and the like, without special sealing measures.

After the glass is damaged, it has sufficient residual bearing capacity and will not fall in one piece: ordinary PVB laminated glass, especially tempered laminated glass, will produce great bending deformation once broken, and there is a danger of falling off the whole piece. When the glass is installed horizontally on the top of the lighting, the risk is even greater. The Beijing Xiangshan Botanical Garden has had an accident in which the glass has fallen. SGP laminated interlayer film laminated glass is good in integrity. The tear strength of SGP laminated film is 5 times that of PVB laminated film. Even if the glass breaks, the SGP interlayer film can bond the broken glass to form a temporary structure after the damage. It has a small bending deformation and can withstand a certain amount of load without falling down the whole piece. This greatly improves the safety of the glass.

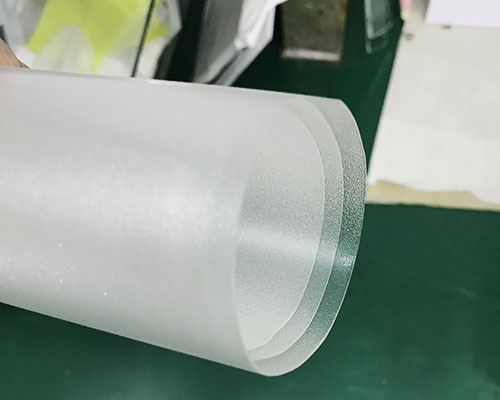

Colorless and transparent, not easy to change color, excellent permeability: SGP laminated film itself is colorless and translucent, and it has good weather resistance and is not easy to yellow. The yellowing coefficient of the SGP film is less than 1.5, and the yellowing coefficient of the PVB film is 6-12. Therefore, SGP laminated glass can better meet the architectural requirements of architects. If ultra-white glass (low-iron glass) and SGP interlayer film are used, the optical effect of ultra-clear laminated glass will be absolutely top-notch.

Mechanical properties of ionic interlayer film laminated glass: The performance of several sheets of glass laminated together depends on the mechanical properties of the interlayer (adhesive film). If the shear modulus G and the tear strength f of the interlayer film are small, the interlayer layer will be greatly slipped when the laminated glass is bent, and the glass will slide relative to each other, and the laminated film does not actually act as a glass. Connected as a whole. These pieces of glass seem to be stacked together, and actually they work separately. The bearing capacity is only the sum of the individual bearing capacities of the individual sheets of glass. On the other hand, if the shear modulus G and the tear strength f of the laminated film are high, the amount of slippage of the laminated film when the laminated glass is bent is extremely small, and at this time, a few pieces of glass can work together as if it were a single piece. The same as glass.

The application of Group SGP laminated glass in large public buildings: SGP interlayer laminated glass has been applied in many large public buildings, which improves the safety of the curtain wall, reduces the weight of the glass, and makes the curtain wall more transparent.

The application of Group SGP laminated glass in super high-rise buildings: Super high-rise buildings are subject to large wind, seismic and temperature changes, requiring high bearing capacity and rigidity of the glass panels, and in case of damage, there must be certain Remaining bearing capacity without falling. SGP interlayer film laminated glass can well meet these requirements.

The application of Group SGP laminated glass in the top of the lighting: SGP laminated glass not only has high strength, but also has sufficient resistance to bending after breakage, and does not fall from high altitude. Therefore, it is especially suitable for horizontal or oblique glass of glass lighting roof. Plate. Used in villas, glass roofs, sun rooms, etc.

The ionic interlayer SGP has not been used for a long time in building curtain wall laminated glass, but its excellent performance has already appeared in the application. The high bearing capacity, safety and permeability of SGP laminated glass are fully demonstrated in large public buildings and glass walls of super high-rise buildings. In the application of glass block, glass floor and glass sun visor, SGP laminated glass has the advantages of impact resistance, safety and no need for edge sealing. Ultra-large size laminated glass and multiple laminated glass products are inseparable from SGP laminated rubber. Membrane, in the future SGP laminated glass continues to expand into other applications, we will see its broader development prospects.

service

service 0769-83382566

0769-83382566